转鼓式洗瓶机

1/5

转鼓式洗瓶机

¥0.00/普通

2013-08-23 10:150分享0询价

参数

- 冠和品牌

- 1普通起订

- 广州产地

广东 广州

0天内发货

0普通

产品参数

- 冠和

- 广东 广州

- 1普通

产品详情

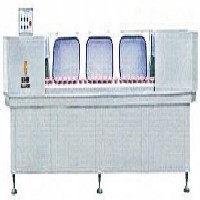

GHXP-1转鼓式洗瓶机

GHXP-1 Automatic rotatoing-drum washingmachine

概述:瓶子由进瓶斜斗进入到超声波清洗槽中,经过超声波清洗后, 由进瓶螺杆送到提升拨轮上进入大转鼓上被机械手夹住,翻转180°瓶口向下,并随着大转盘顺时针转动,大转盘下部6组装有喷针的喷水(气)管跟踪将喷针插入瓶内按程序进行二次循环水,一次压缩空气,一次新鲜水,再二次净化压缩空气喷洗,同时在瓶外也进行水的喷洗,以此完成瓶子的清洗工艺,洗净瓶子后由机械手将瓶子翻正(瓶口向上)再通过拨轮将瓶子拨入下道工序.

技术参数:

1. 适用规格:口服液瓶、西林瓶

2. 工作头数:40/60头

3. 生产能力:160~300瓶/分钟

4. 耗水量:0.6~1m3/h 水压:0.3~.4Mpa

5. 耗气量:30m3/h 气压:0.35~0.45Mpa

6. 电 源:380V 50Hz

7. 功 率:13kw

8. 重 量:1800㎏

9. 外形尺寸:2500×1000×1200(mm)

特点:

· 结构紧凑,性能稳定,操作简易,维修费用低。

· 多规格,多用途。

· 可联动使用,也可单机使用。

· 采用PLC控制,人机界面操作洗瓶工艺,超声波可根据客户需要定制。

· 具有残水去除装置。

· 采用螺杆进出瓶,无卡瓶,破损。

· 清洗质量符合GMP规范要求

Introduction:

Bottles gets intoultrasonic cleaning trough by bottle-entering inclined hopper,after ultrasonic cleaning, bottle screw carrys them to dial wheeland then into big rotor drum, held by manipulator, fliped 180 °with bottles down, turning clockwisely with big wheel.under big wheel,the 6 sets of (water/air)jet nozzle with spray needles will insert sprayneedles into bottles, and then work according to set program:Second recirculated water, one compressed air, one fresh water,& second purified compressed air spray washing. At the sametime, water also spray bottle outer, thus finishing the wholewashing part. Then manipulators turn bottles with neck up, and getinto next part by dial wheel.

在线留言

店铺最新

- 转鼓式洗瓶机

- ¥0.00

在线问

在线问

最近来访记录