氧化铝陶瓷板95陶瓷

Wear-resistant alumina mosaic, Wear-resistant alumina tile

产品特性/ Characteristics:

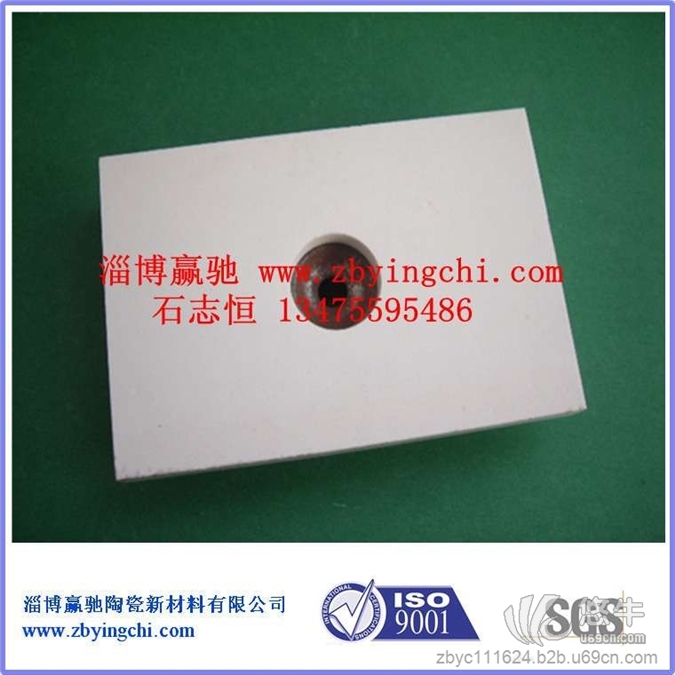

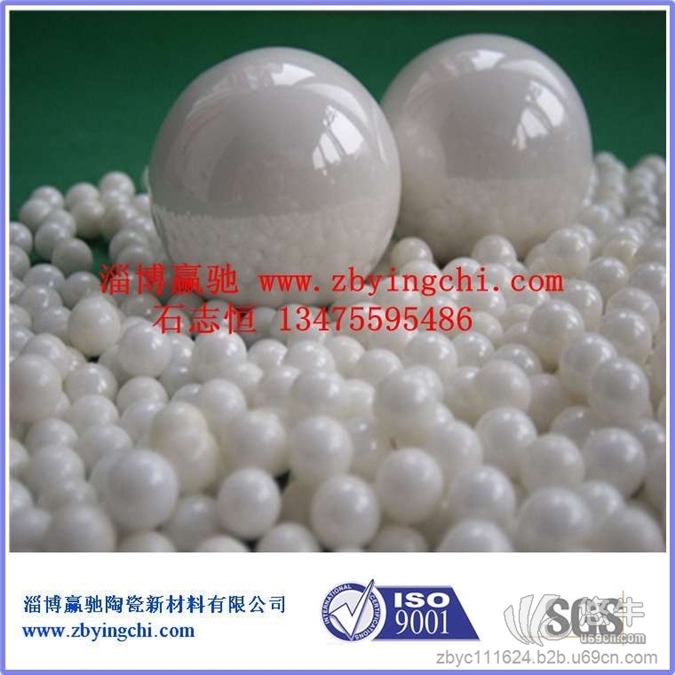

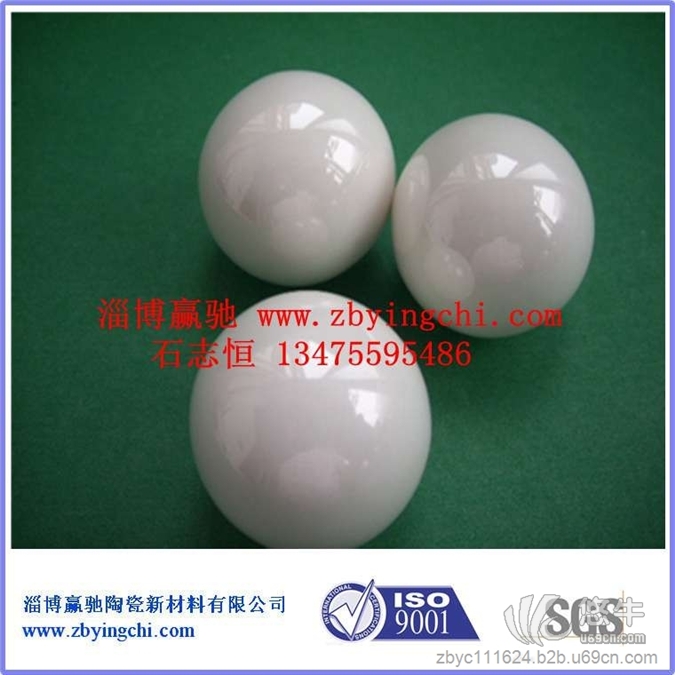

耐磨氧化铝陶瓷衬片,耐磨氧化铝陶瓷衬板,氧化铝陶瓷旋流器内衬弧板其洛氏硬度为 HRA80-90,仅次于金刚石,耐磨性能远超过耐磨钢和锰钢。可直接将耐磨氧化铝陶瓷衬片,耐磨氧化铝陶瓷衬板,氧化铝陶瓷旋流器内衬弧板粘结到耐磨设 备内壁,采用高温粘结剂在250℃下可长期运行不老化,利用氧化铝陶瓷的耐磨特性延长设备的使用寿命;将耐磨氧化铝陶瓷衬片,耐磨氧化铝陶瓷衬板与橡胶及 钢板复合后,作为耐磨设备内衬,同样能显著提高设备的使用寿命。

Wear-resistant alumina tile are a special aluminum-oxide ceramic developed specifically for use as a wear resistant surfacing material. Harder than any naturally occurring substance except diamond, almost any surface subjected to sliding abrasive action can be protected with alumina ceramic. For example, it is being used to protect the metal surfaces of chute, bins, and hoppers, vibrating feeder pans, cyclones, centrifuges, conveyors, elbows and other equipment which is subject to severe abrasion.

Wear-resistant alumina tile are easily installed by plant maintenance people. They are available in standard brick and tile shapes as well as in special shapes to fit irregular contours.

Fastening the ceramic to metal or other backing material is accomplished by using cements, by mechanical means, or by a combination of cementing and mechanical attachment. The type of installation will determine which of the following methods to use.

氧化铝陶瓷板95陶瓷产品参数/Technical data:

|

项目/产品 Item/Product |

92系列 92Series |

95系列 95Series |

|

Al2O3(﹪) |

≥92 |

≥95 |

|

Hardness(Mohs) |

9 |

9 |

|

Water Absorption(%) |

≤0.02 |

≤0.02 |

|

Fracture toughness(MPa) |

3.65 |

3.75 |

|

Bending strength(MPa) |

255 |

275 |

|

Density(g/cm3) |

≥3.60 |

≥3.65 |

|

Compressive Strength(Mpa) |

≥850 |

≥900 |

|

Thermal Conductivity(W/m.K) |

16.8 |

16.8 |

氧化铝陶瓷板95陶瓷应用领域/ Applications:

适合火电、钢铁、冶炼、机械、煤炭、矿山、化工、水泥、港口码头等企业的输煤、输料系统、制粉系统、排灰、除尘系统等,一切磨损大的机械设备上均可根据不同的需求选择不同类型的产品。

We can supply alumina ceramics for the coal, steel, pulp & paper and power industries.

That is also best suited for anti-wear lining applications in the grain handling and mining industries.