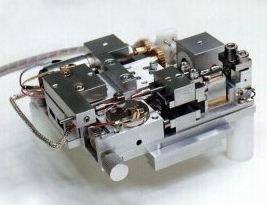

Micromac 3d microDICE

system 激光切割

Cost,

quality, and throughput are major factors of success for SiC based devices in

the semiconductor industry. 3D-Micromac answers this challenge with its

brand-new microDICE™ system.

The

revolutionary, high-performance microDICE™ laser dicing system brings

TLS-Dicing™ technology (Thermal-Laser-Separation) to semiconductor‘s back-end.

The

microDICE™ separates wafers, including SiC, into dies with an outstanding edge

quality while increasing the yield and the throughput.

In

addition, microDICE™ considerably reduces the dicing cost per wafer. Due to the

contactless laser machining there is no tool wear and no expensive consumables

required. This results in excellent cost of ownership during the whole

life-time of the dicing system.

Compared

to traditional separation technologies microDICE™ provides a much higher

process speed and better throughput leading to high-volume production of SiC

based devices. microDICE™ is suitable to dice wafers up to 300 mm wafer size.

The

modular standard system configuration consists of:

· Cleaving funtion

· Soft scribe function

· Micro stretching function